At Anup Engineering we encourage both the enthusiasm and experience that our team of engineers and draftsmen bring on board. This lays the foundation of the engineering expertise that we are well known for. From detailed engineering requirements to thermal design, FEA analysis and beyond – we have the in-house capability to provide engineering solutions that meet various international codes and quality standards from across the globe.

Codes & Standards

- ASME Sec I

- ASME Sec VIII Div. 1 & 2

- EN 13445

- TEMA

- PED

- IBR

- AS – Australian Standard

- ARH (Algeria)

- AD-2000 Merkblatt HP0

- GOST/TR CU- Russia

- SANS- South Africa

- MOM- Singapore

- DOSH- Malaysia

- PED/CE- Europe

- NR13(Brazil)

- CN (Canada)

Software

-

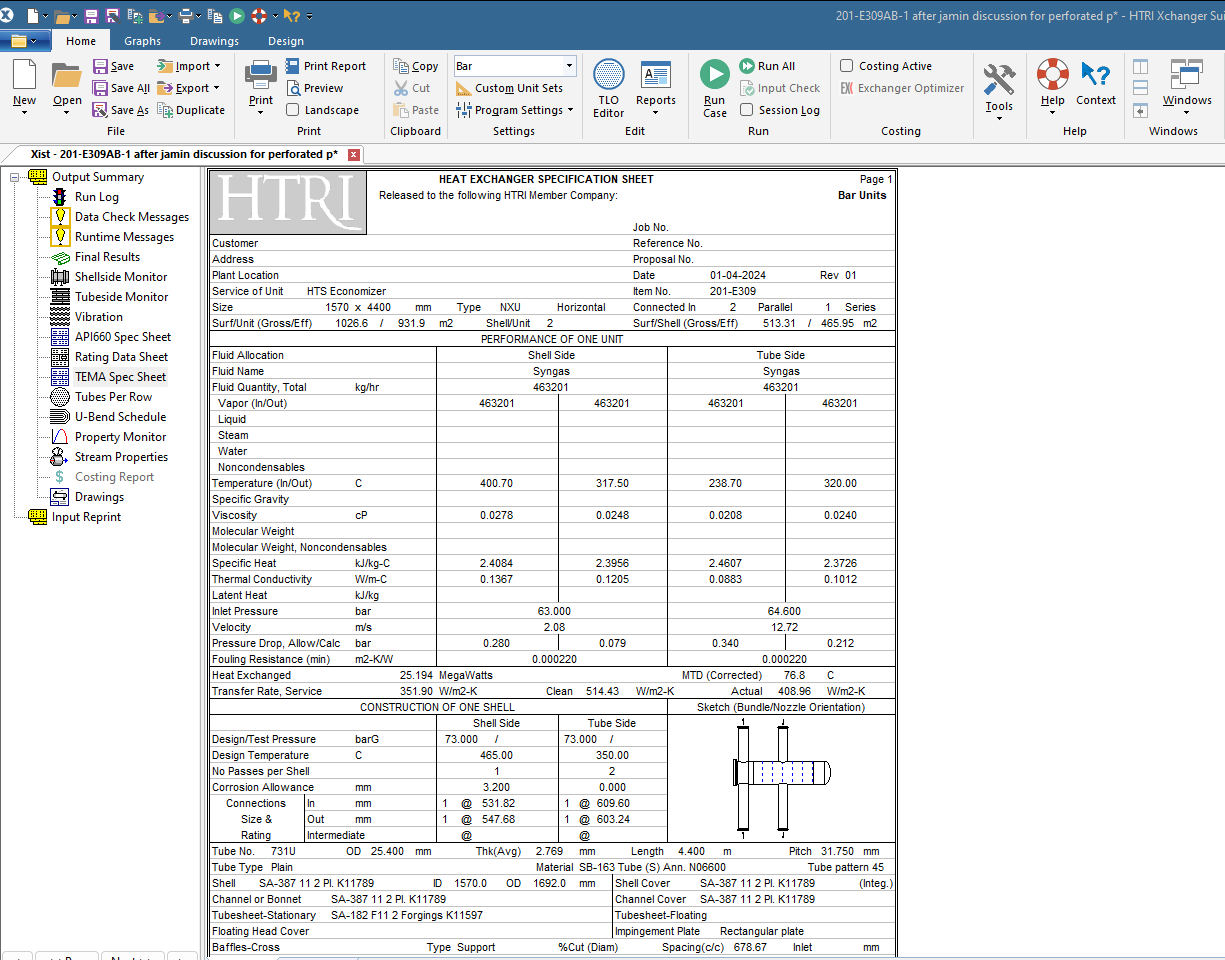

Thermal Design

HTRI with Xist 9.1

-

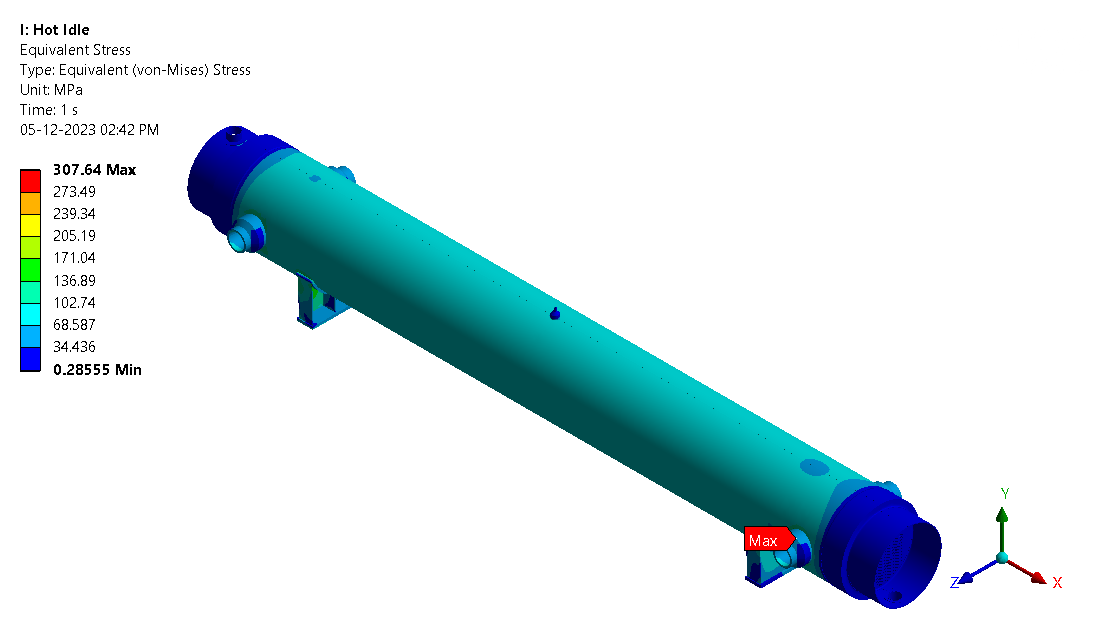

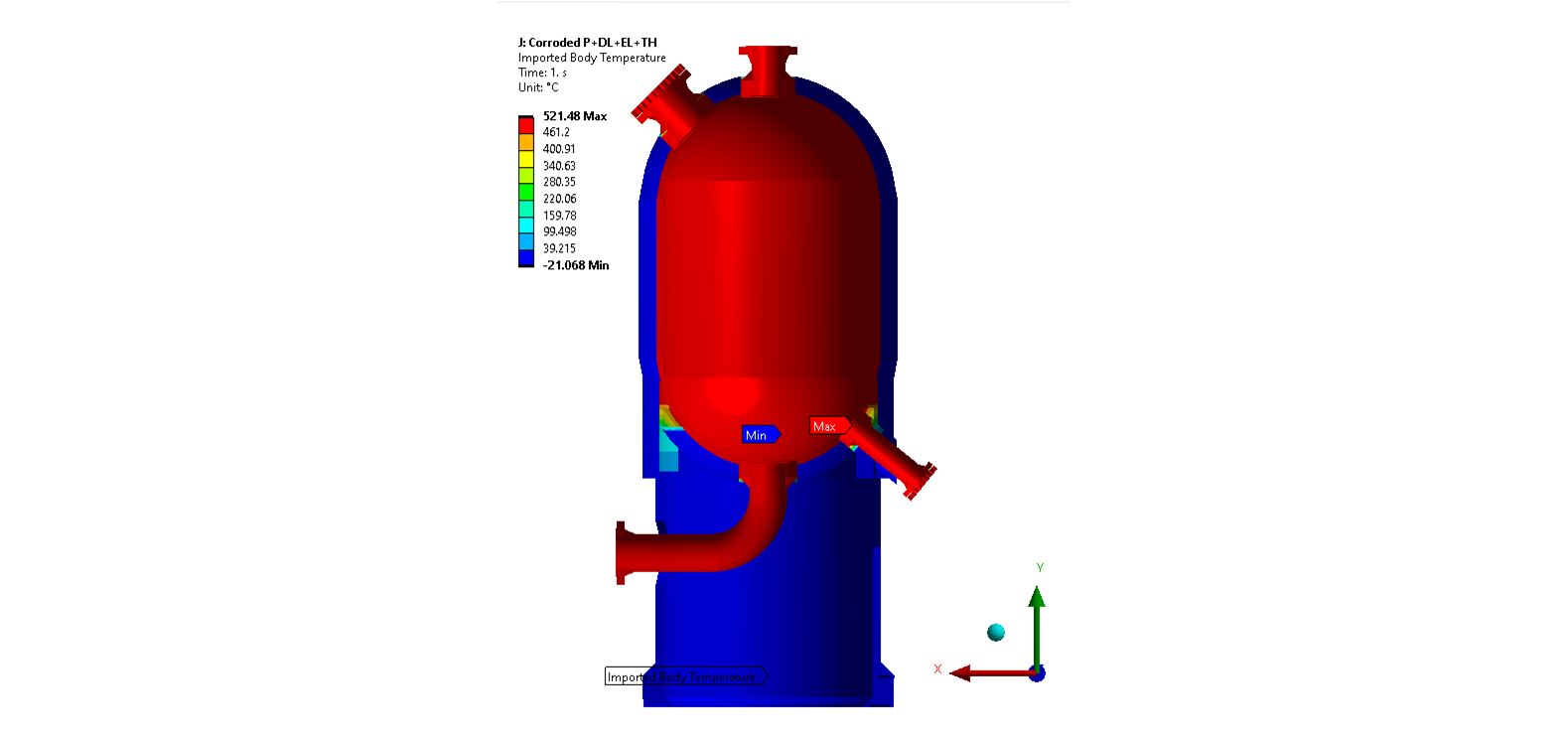

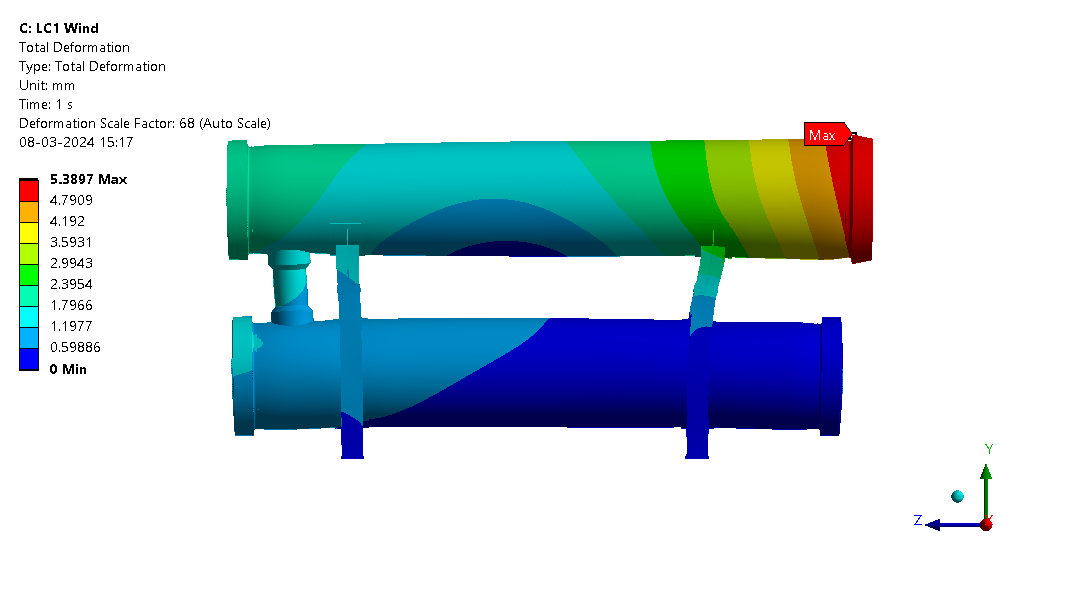

FEA & Fatigue Analysis

ANSYS 23 R1; NozzlePRO 21

-

Mechanical Design

PVElite 2025; Microprotol

-

3-D Modeling

PDS (Inventor); 3D PV 24

-

Drafting

AutoCAD 2024

Our manufacturing facility in Ahmedabad, India is spread across an area of 45,000 sq. mtrs. with 6 heavy and 4 light fabrication bays. The high-end as well as versatile nature of our facility can is testified by the fact that we can manufacture equipment ranging from 20 MT to 450 MT with equal ease.

The ingeniously designed unit has the capability to manufacture equipment ranging from 20 MT to 800 MT with equal ease and the specifications include:

-

Diameter

Up to 8 meters (Larger dimension can be evaluated in case to case basis)

-

Length

Up to 80 meters in single piece (Fabrication)

-

Weight

Up to 800 metric tons per equipment

- Cold Rolling upto 200 mm plate thickness with 4 m width

- A world class Clean Room

- Deep hole CNC drilling machines for drilling up to 1500 mm deep holes (tubesheet drilling)

- CNC Plasma cutting machine for CS plates up to 300 mm thick and SS plates up to 110 mm

- Modular Heat Treatment Furnace for Stress Relieving of equipment in a single piece up to 40m.

- Shot Blasting Enclosure

- State-of-the-art Painting Booth

With decades of experience in fabrication we have acquired a high level of skill in the core process of welding. We possess over 1800 qualified welding procedures and high degree of expertise in various materials and welding processes.

Our constant endeavour to automate most of the welding processes we use is a characteristic that sets us apart and provides us with a competitive edge along with highest quality.

Welding Processes

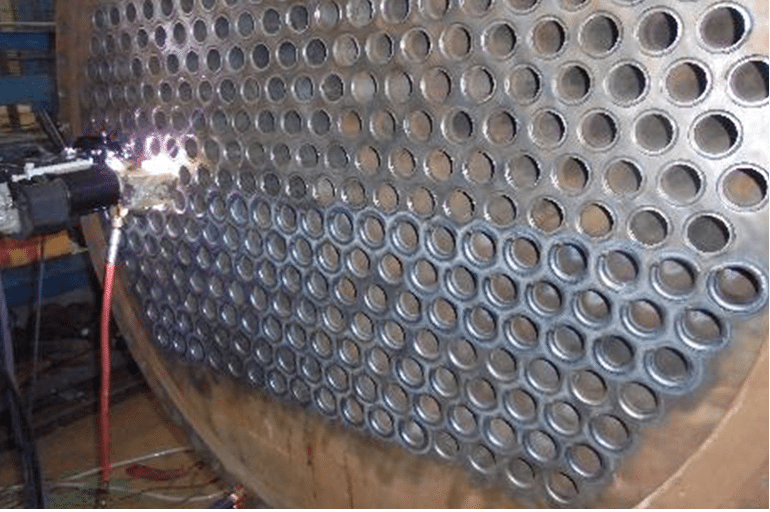

- Automatic Orbital Welding for Tube to Tubesheet joints

- Electroslag Strip Cladding (ESSC) for weld overlay

Special Processes

- Submerged arc welding (SAW)

- Gas tungsten arc welding (GTAW)

Tube to Tubesheet joints welding

- Shielded metal arc welding (SMAW)

- Gas metal arc welding (GMAW)

Tube to Tubesheet joints welding

- Narrow gap welding

- Flux cored arc welding (FCAW)

Metallurgies

| Exotic | Cobalt Alloy, Titanium Gr. 1/2/16, 2RE69, Alloy 625, Alloy 825, SS 904/904L, Cu-Ni alloys, Hastelloy C22/276, Monel. |

| Low Alloy Steel | 2.25Cr 1Mo, 1.25Cr 0.5Mo, 5Cr 0.5Mo, C 0.5 Mo, 3.5% Ni, HT Steel |

| Stainless Steel | 304, 306, 321, 310, 317, 32304(LDX), 31803, 32750, 405, 410S, 439 |

| Carbon Steel | Boiler Quality, HIC, NACE, LTCS |

Quality forms the core of our business philosophy. The equipment designed and manufactured in our facility is made to match the most stringent quality standards. It is this trust in our quality that has helped us form a dedicated client base over the years and brings our customer back to us with repeat orders.

• ISO 9001:2015, ISO 14001:2018 and ISO 14001:2015 certified.

• ASME U, U2, S as well as NB & R stamps.

• Statutory compliances with country specific regulations such as PED/CE, SANS, GOST TR-CU, DOSH, MOM, ARH (Algeria), NR13(Brazil) and CN (Canada)

• In- house NDT facility for PMI, PT, UT, RT, TOFD (Time of Flight Diffraction) and Helium Leak Test.

• In-house NABL Approved Lab for Testing

Set in the vibrant city of Ahmedabad, our facility is conveniently located close to some major national highways, ensuring smooth logistic operations by road. It also has easy access to all the major sea ports in the West of India. The Mundra and Kandla ports of Gujarat are 400 km and 350 km away, whereas the Mumbai port is at a distance of 550 km from our facility

Our dedicated logistics team further ensures the seamless movement of equipments from our unit to our client’s site, anywhere across the world.