Welcome to the cutting-edge world of industrial centrifuges, where Anup Engineering pioneers innovative solutions for various industries. Let’s explore two remarkable types of centrifuges that are transforming industrial processes – Horizontal Peeler Centrifuges and Basket Centrifuges.

1. Horizontal Peeler Centrifuges

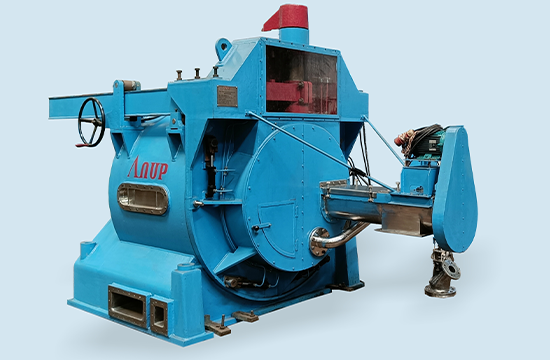

Anup Engineering’s Horizontal Peeler Centrifuges stand as a testament to precision and efficiency in separation processes. These centrifuges are ideal for applications requiring precise solid-liquid separation. They have a horizontal design that maximizes space use and improves ease of operation.

Our Horizontal Peeler Centrifuges have innovative characteristics such as high-speed operations and improved peeling mechanisms. These centrifuges effectively remove excess moisture, leaving only dry solids and assuring perfect separation performance. Industries ranging from pharmaceuticals to chemicals rely on the reliability and robustness of Anup’s Horizontal Peeler Centrifuges.

2. Basket Centrifuges

The Basket Centrifuges redefine the standards of liquid-solid separation, designed for versatility, these centrifuges cater to diverse industries with varying separation requirements. Our basket design provides efficient impurity removal, making it a vital tool in processes that require high- quality outputs.

The Basket Centrifuges that we engineered deliver consistent and reliable results. With adjustable features and a user-friendly interface, these centrifuges enable enterprises to achieve maximum productivity without sacrificing quality.

Anup Engineering’s Horizontal Peeler Centrifuges and Basket Centrifuges demonstrate their commitment to excellence via innovative and precise design. Our passion for developing cutting-edge solutions that move industrial processes forward evolves along with the industries.